Some people were saying it is not worth to resque. "It is a piece of scrap" - they said. And there was a piece of truth in it. Outer look was quite ok, but it was not kind of device we would put on some exhibition for audience. Scratched cover indicated about difficult life. After closer look, we found that filter switches and potentiometers almost do not move. Rest was only worse. Burned bulbs, cut power cable, rusted parts, broken fuses and wires, demaged power ending and detached transformer.

Schematic

As for many old polish devices like this, it is fairly easy to find schematic. We put this one here for others:

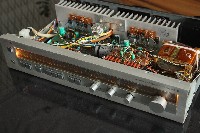

Internal wire connections creates real spagetti. To make this surgery effective, we had to disconnect all of them. Only after that move we could start cleaning and fixing it. When old dust had been removed, going module after module, we were removing rusted and demaged parts. After a few evenings main board was ready and waiting for new parts.

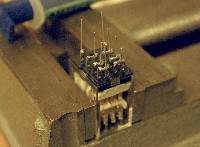

Buttons

Really amazing was condition of two buttons, which almost fall apart in my hands. There were no chances to resque them, so as always in such case, we went to transprantology center for new organs. When only they arrived, we put them into right place.

Potentiometers

Their outer look was satisfying, unfortunately during rotation, they were giving a sound like they would be full of sand. After unsoldering it they also fell apart on tinny pieces. Carbon track was broken. It was not so easy to find good replacement and we had to do sophisticated tricks to fix them. We couldn't let such a detail to fail our "Phoenix" project.

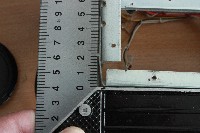

Front panel

We couldn't figure it out, what had happened that in well assembled, never serviced model, some elements of fron panel were demaged. After short analisis it turned out, that only parts mounted on PCB are broken. Looking on this patient from different angles we found, that this element has been moved in parallel damaging those parts. Taking into account force that is needed to this type of move and broken transformer holders, we can suspect that it has fallen from some high level above the ground. We will consult this with family but we are pretty sure looking at dent in the corner. Our blacksmith did his magic and all holes and parts fit again to eachother.

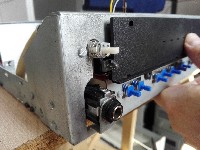

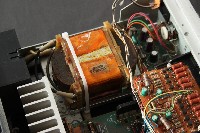

Transformer

As I have already mentioned, this 1,5kg monster, had his plastic mounting holders been demaged with some gently hit. With this weight, new construction have to be somethin rock solid. That is why it was attached to some metal sleight with epoxy glue and plastic clamp.

Durring initial run, we found that one terminal does not give any voltage. That was serious threat to our project because it is really hard to find equivalent and it is also expensive. Root case of this problem turned out to be a broken tinny wire. Fortunately we were able to fix it.

Bulbs

Both of them were in their sockets, but those we not holding it position on front panel. Wrong voltage models (12V) were getting so hot, that they melt the plastic around it. This plastic became fragile and finalt cracked. On the beggingin I wanted to use some LEDs, unfortunately that would require additional circuit of some step down voltage regulator. Bulbs here are supplied with 44V AC. After rectifier it will be even more. Fortunately I managed to find 24V that were used originally. Thanks to 3D printing we made supports to put them in right position.

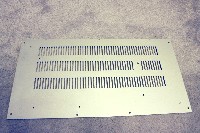

Cleaning

This guy had a hard life. It has to spent some time in very adverse environment. It case from outside was scratched, dirty in some places also rusted. Although cleaning front panel was fairly easy, but top and bottom cover had to be repainted to get shiny look. This time, our paint shop did its best and after all scratches haven't remained any sign.

As a final finishing, polishing chinch connectors and remove dust from plastic ones.

Improvements

Delayed speakers switching on mechanism

On the main board, one can easily find area with not mounted elements. Those missing parts are responsible for delayed speakers switching on. Its purpose is to eliminate loud bum effect just after turning power amplifier on. After receiving agreement from family, we decided to add this circuit. When it works, a few seconds after turning device on, one can hear characteristic 'click'. In modern power amplifiers there is some additional LED indicating that it is on. We didn't want to make new hole in front panel, so we used empty place for central diode in power meter. Unfortunately, we couldn't get original relay, but there are planty of similar available. We only had to fit its connections.

Phones

Legacy headphone socket was quite dirty and oxidized. When we remove it fot cleaning purposes, it turned out, that it is a basic version without internal switch, that change its state, when plug is in. We had better one on the table and in better condition. After another talk with family we have added this feature of disconnecting speakers when headphones are on - privacy mode. Originally it must be done with addidional switches.

Bring up

Never, after such serious surgery, we don't wake up patient at once. Just part after part removing discovered problems. In this case, it went quite smooth (I don't count broken connector in transformer). A bit of attention required this delayed circuit, because time needed some adjustments. When everyhing was running, remaining part was only regulate bias current and testing. At this point we found that potentiometer responsible for balance did keep it parameters and signal in both channels was not equal.

Summary

This patient was really demending, but final effect and recovered voice are the best award for this whole time spent on it. We have hope that family will also be stisfied.